Metalworking in perfection

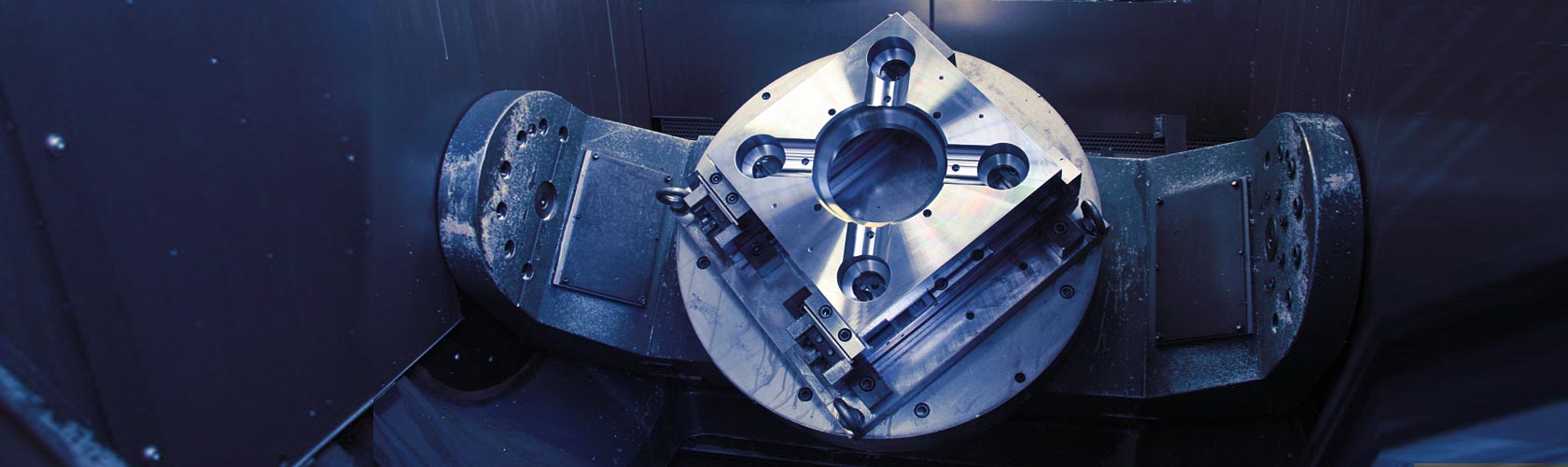

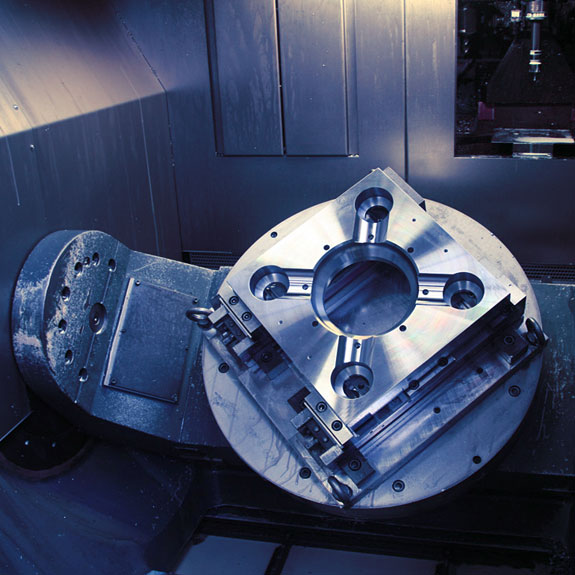

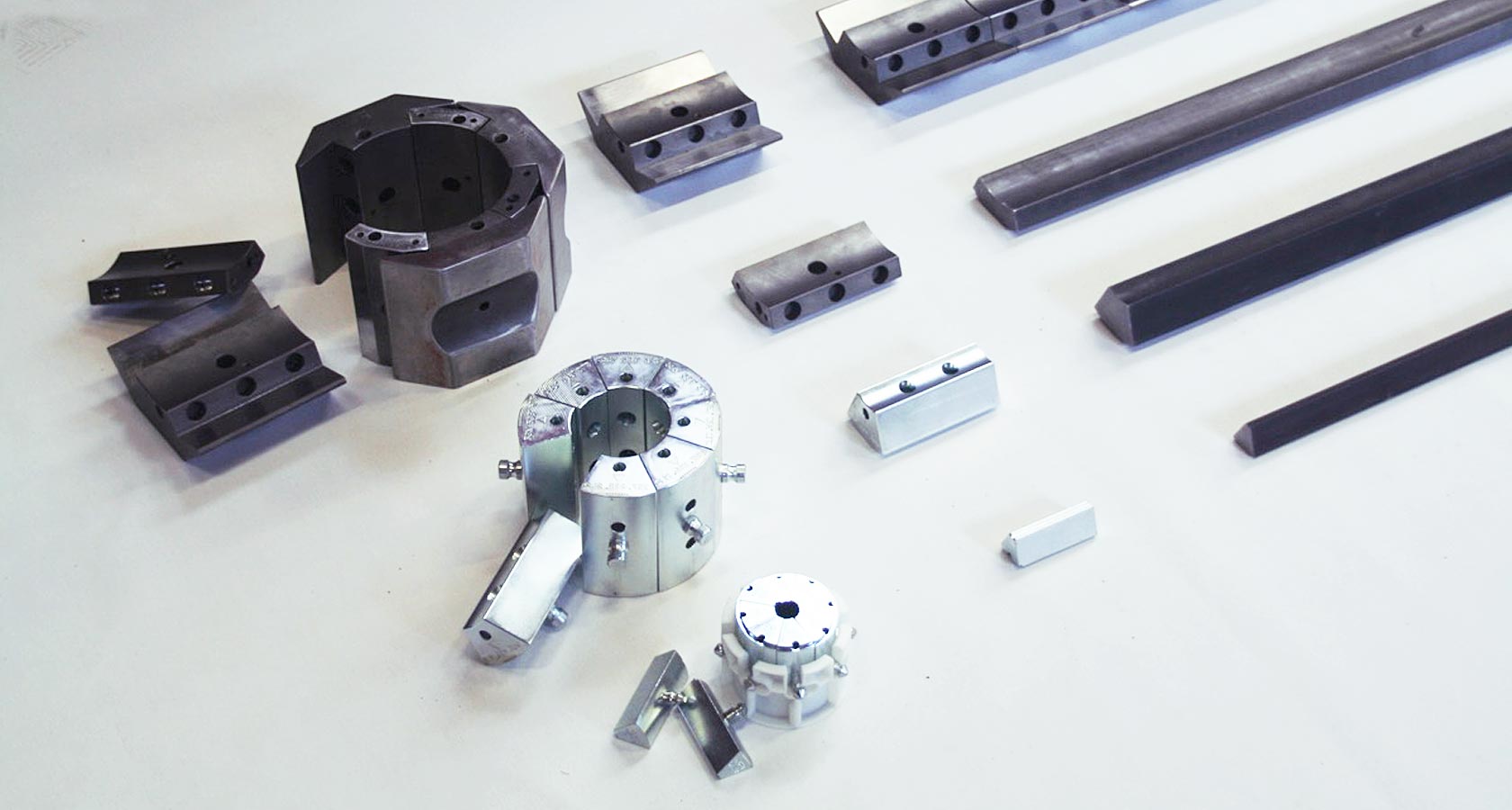

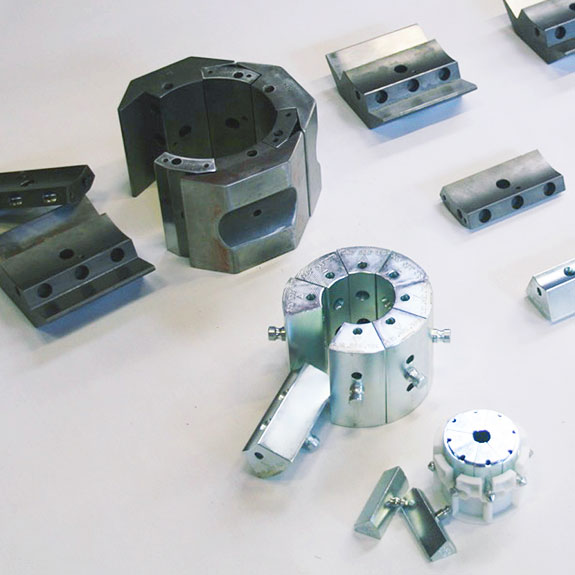

5-axis milling, turning and grinding of complex metal parts and the assembly of subassemblies are the competencies of the team at Uniflex CNC Metalltechnik GmbH in Großalmerode near Kassel. The company was founded in 2001 and is now located right next to the former Hirschberg mine. Among other things, the press jaws for the press machines of Uniflex Hydraulik are manufactured here with the highest precision.

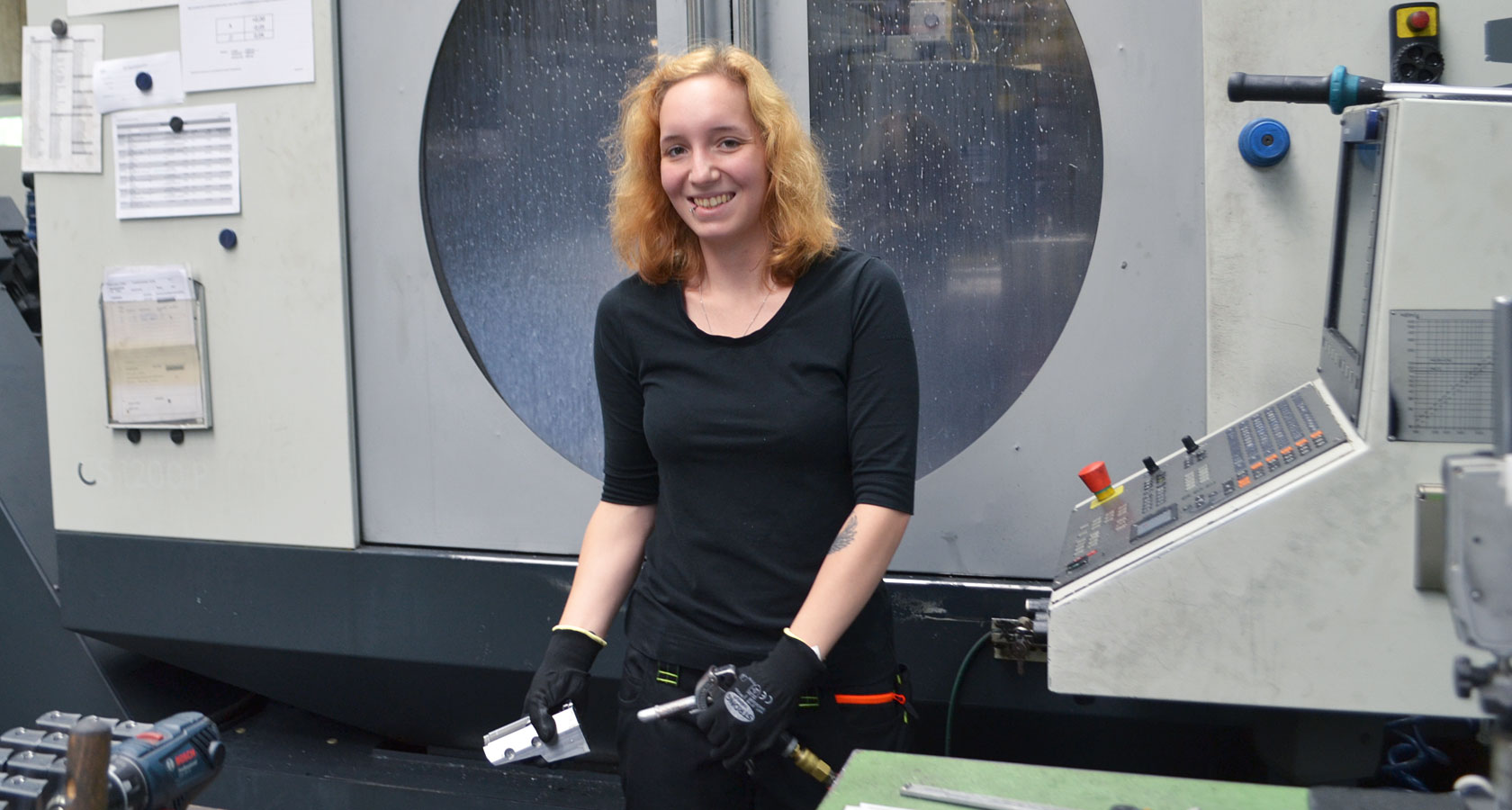

TEAM UNIFLEX CNC Metal Technology

My name is Helmut Hartung. I have been with the company longer than Uniflex has existed. In 1979, I started as a factory fitter at Hirschberg Colliery. At that time, that was the main branch of the Waitz Group. The colliery has been closed for a long time. At some point, nobody wanted to buy our coal anymore. One day we were standing at the workbench in the morning and they said "Boss is buying a new company, who wants to join?" and at first I was the only one to sign up.

I was the first from the colliery to join Uniflex. Later, three more colleagues came along. The work at the colliery was rough and tumble, at Uniflex CNC they are comparatively sensitive. The change caused me some sleepless nights. But I got used to it. Now I'm doing the assembly here.

Hi, I'm Julia and I work in production planning at Uniflex Metalltechnik. At the end of 2024, I started managing the company's social media channels. I was asked to do this because my husband already worked at the company and they knew about my training as a media designer. Then, at the beginning of 2025, I was asked to help with incoming invoices. Shortly afterwards, I was offered a permanent position in production planning. So in March, I left my hectic job as a medical assistant and joined Uniflex on a permanent basis. My job is very varied – just like in a doctor's office, but without the constant stress. And variety has always been important to me!

Despite working in an office, I have a lot of contact with production—it's always fun with my colleagues. I particularly appreciate the flexible working hours, which are a real blessing with a child at home. It's also a privilege that my dog Amy is allowed to come with me. She is our “feel-good manager” and dashes through production every morning to say hello to all the employees.